EMS - E2MS

EMS / E2MS Electronic Manufacturing Service

Our service for you

Are you planning to develop an electronic product or are you looking for a partner for subcontracting electronics services or an EMS/E2MS service provider? We develop the electronics you need, create an optimal manufacturing solution and produce on state-of-the-art systems.

What we do for you:

- Electronics development tailored to your requirements

- Optimized manufacturing solutions and high-quality production

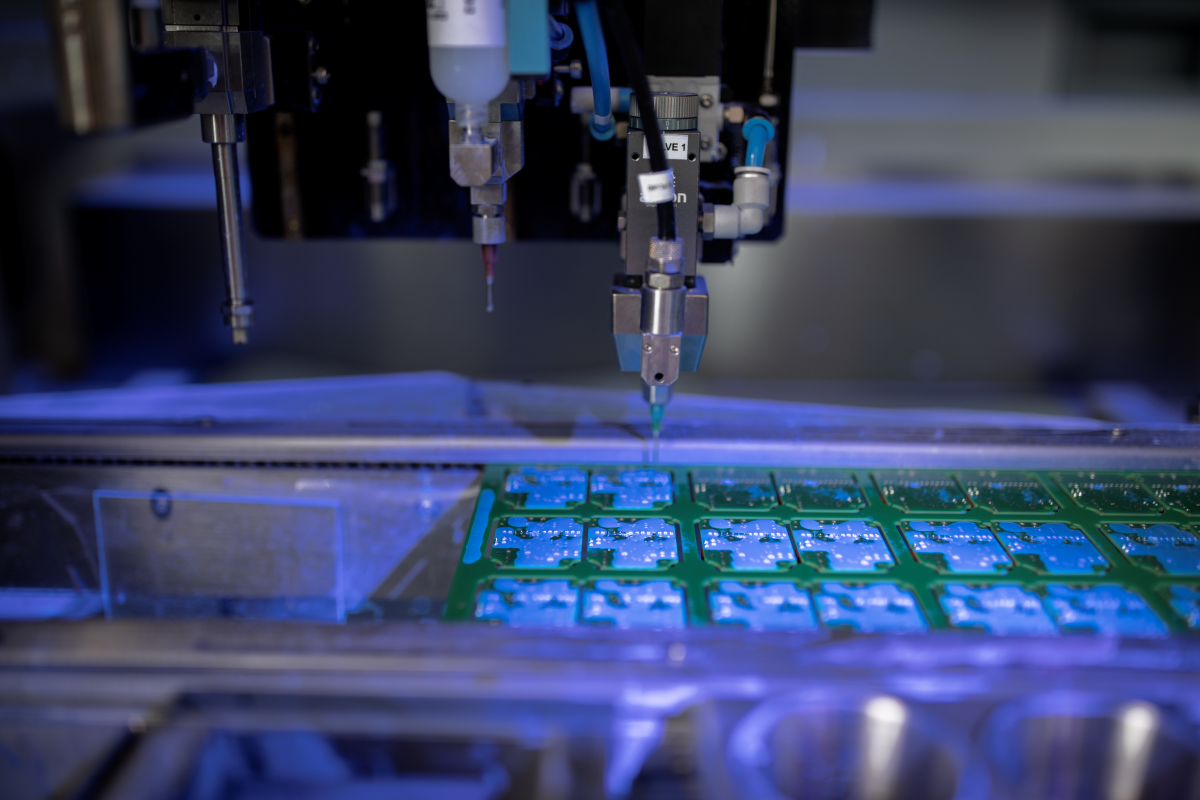

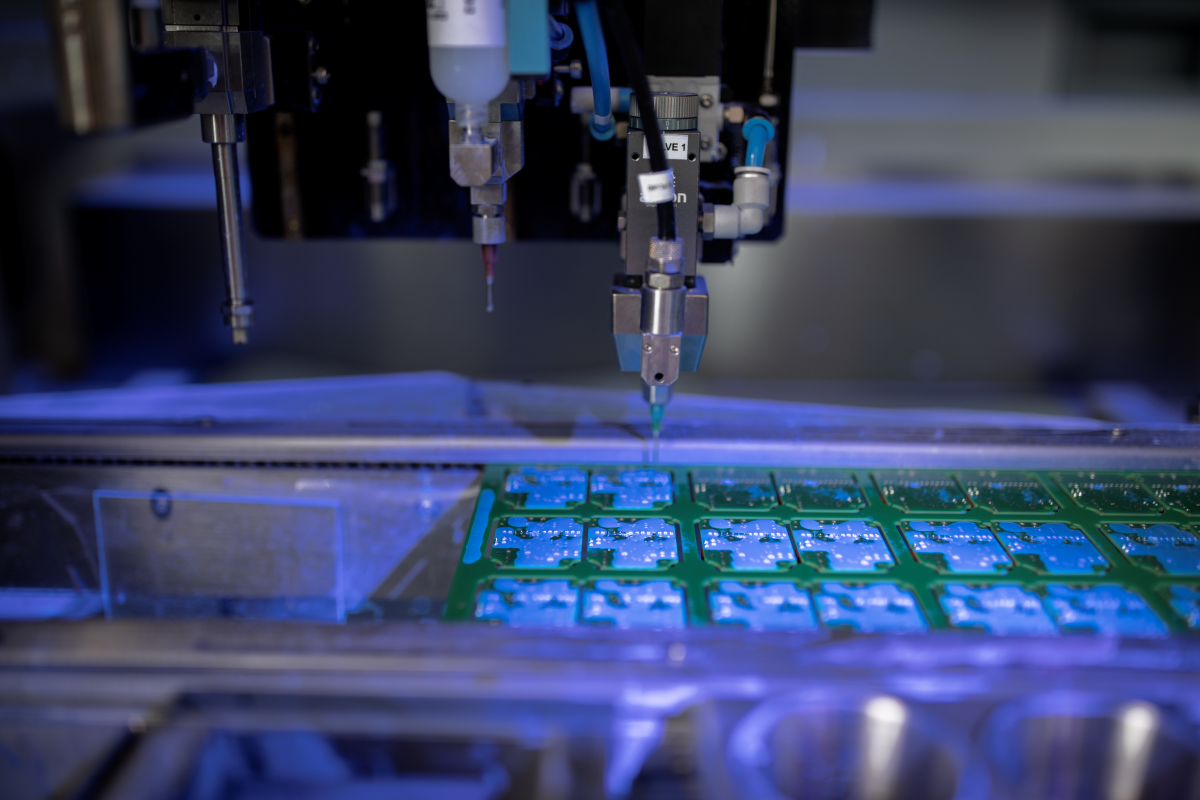

- State-of-the-art equipment: PCB cleaning system, THT and automatic SMD assembly, automatic optical inspection systems, fully automatic potting and coating system, fully automatic inlinetester, laser marking, and more

- Also available as partial services, e.g., protective coating only

Why Dickert Electronic:

- Strong, long-term partner focused on your goals: improving quality, optimizing electronics manufacturing, and reducing costs

- High-quality manufacturing for small, medium, and large series

- Transparent prices and individual consultation – your product is the focus

We always provide you with the right solution in terms of technologies and processes for a wide variety of projects. Trust in our expertise and realize your electronics projects safely and efficiently.

Dickert Electronic

EMS/E2MS service and development expertise

New products bring new challenges with them, and the requirements are constantly increasing with the ever higher targets for high-performance electronics and thermal management. When assembling aluminum PCBs, for example, special expertise is required to join different materials together effectively and to a high standard.

We have the solution. Contact us, our team will be happy to advise you.

Mit unseren Referenzen möchten wir Ihnen einen Einblick in die bisherigen Projekte geben.

At our location in the heart of Germany or in the middle of Europe, we develop and manufacture quality electronics for you.

We would also be pleased to work for you. Please contact us, we are looking forward to your inquiry.

Your professional offer with best price guarantee

Send us the following information now and we will create your personal offer:

- Bill of materials / BOM, preferably in CSV, Excel file formats (without macros / without scripts).

- Component specifications in values with manufacturer, manufacturer part number and MPN.

- In the bill of material / BOM, there should be a marking for fixed specified components (no alternatives allowed).

- Details of special parts to be used (supplier, provision/price).

- PCB data / Gerber data, optional: project data if necessary the original CAD data (e.g. Eagle)

- PCB special features: Design, position printing, UL, protective lacquer, number of layers

- Pick and place data for top/bottom side, preferably in CSV, Excel file formats

- Pick and place data for top/bottom PDF (searchable)

- Pictures of the board and/or the device from all directions, alternatively 3D data

- What quantities are required in advance as samples / release samples?

- Details of product tests, inspections, final test, functional test (the following tests are always available due to the system: Reflow paste print(SPI), SMD-AOI, THT-AOI, solder joint AOI)

- Is this a one-time order? If yes, the material procurement would be piece-precise and somewhat more expensive. On the other hand, there are no surplus components.

- Annual requirement quantity / Series purchase lot sizes / Blanket order / Contract

- If follow-up orders are in prospect, packaging units would be calculated and ordered, which are cheaper in unit price, but lead to surplus components. Without a follow-up order, these will be invoiced subsequently.

- Your time planning / desired dates / fixed dates

- Information on board / device identification

- Information on packaging / transport packaging / delivery / shipping

- Without other information we always assume complete material procurement